Three liquid chemistries, solid state cells, and flatter battery packs.

Toyota, the world’s largest automaker, has a problem. Although the company is famous for pioneering lean methods of manufacturing and being an early pioneer of hybrid electric powertrains, the switch to battery electric vehicles caught it somewhat unprepared. As rivals locked up contracts for critical minerals and formed joint ventures with battery makers (or built their own), Toyota has appeared to fall behind.

Now, it has released a new roadmap showing how it will regain competitiveness and sell 3.5 million EVs by 2030.

After some early experiments with electric-converted RAV4s (including a partnership with Tesla), Toyota has finally released a modern BEV, the bZ4x. The car had a difficult launch—a recall for wheels falling off will lead to that—but a week’s test of a bZ4x exceeded our low expectations. A look at the car’s specs makes clear Toyota’s problem, though: There are different battery packs for the single-motor and dual-motor versions, made by Panasonic and CATL, respectively.

The slow going on BEVs cost CEO Akio Toyoda his position earlier this year, and he was replaced by former Lexus boss Koji Sato, who created a new organization within Toyota called BEV Factory, which has the mission of developing next-generation EVs for Toyota in 2026.

“We will need various options for batteries, just like we have different variations of engines. It is important to offer battery solutions compatible with a variety of models and customer needs,” said Takero Kato, president of BEV Factory.

Four solutions

To that end, Toyota is working on four different solutions. Three of these will use liquid electrolytes and are meant for different applications.

A performance-focused liquid electrolyte lithium-ion battery is slated to be the first to appear in 2026. Toyota says it’s targeting a 20-minute fast-charging time and wants these cells to be 20 percent cheaper than the cells used in the bZ4x. The company plans to use this in a BEV that can travel almost 500 miles (800 km) on a single charge.Advertisement

For lower-cost vehicles, Toyota is looking at lithium iron phosphate cells, a chemistry that’s already extremely popular in China and is being used by Tesla. Toyota plans to construct these as bipolar batteries, where the active materials for the anode and cathode are on either side of a common electrode carrier rather than having separate electrodes for each. (Toyota already uses this approach for the nickel metal hydride batteries it uses in many of its hybrid models.)

LFP cells are targeting a 40 percent cost reduction compared to the bZ4x battery and 20 percent more range. LFP cells don’t charge as fast, but Toyota wants a 10–80 percent DC fast-charging time of 30 minutes. If it pans out, the company expects these cells in 2026 or 2027.

There’s also a high-performance lithium-ion chemistry in development, though it may not be ready until 2028. Toyota wants to combine its bipolar electrode structure with a high percentage of nickel in the cathode to create a pack with extremely long range—up to 621 miles (1,000 km). But it’s also targeting a 10 percent cost reduction compared to the performance-focused pack mentioned earlier.

The fourth battery technology is one that Toyota has talked about a lot in the past—solid state. Both electrodes and electrolytes in a solid state battery are solid, which means the battery can be smaller and lighter than a cell with liquid electrolytes.

The technology is tantalizing, but it’s troubled by the formation of dendrites—spikes of lithium crystals that can grow and puncture the cathode. Toyota says it has made a breakthrough in durability for lithium-ion solid state cells—it’s being coy as to exactly what—that has allowed it to switch to putting these batteries into mass production, with commercial use scheduled for 2027 or 2028.

Interestingly, Toyota was originally planning to use solid state cells in its hybrids only, but it appears to have revised that idea and will put them in BEVs, with a target range of more than 600 miles and a fast-charging time of just 10 minutes.

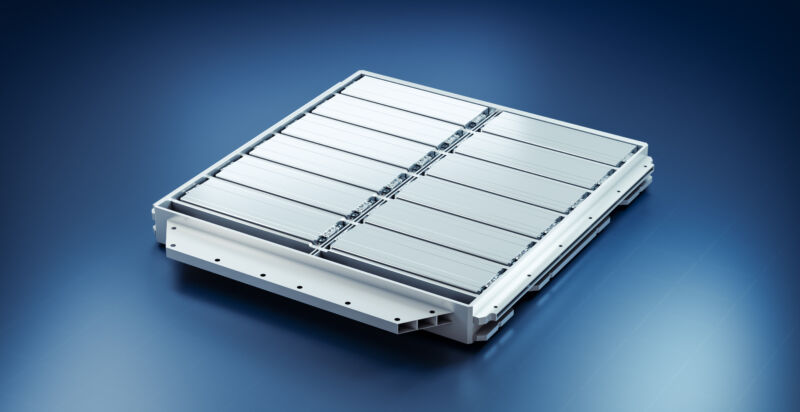

Flatter batteries

A final note in Toyota’s battery strategy is one that many of us will welcome. Toyota says that in addition to working on these four different battery types, it’s also putting a lot of effort into shrinking the height of a battery pack, from 5.9 inches (150 mm) to 4.7 inches (120 mm) or even 3.9 inches (100 mm) tall.

Currently, the thick slab of batteries required by an EV means they’re much easier to package in a crossover or SUV, but with a consequent increase in frontal area and therefore more drag when pushing through the air.