It moves the reduction gear and CV joint to the wheel hub.

We like weird new engineering ideas here at Ars, and today we have a particularly interesting one in the realm of electric cars. It’s called the Uni Wheel, and it has been designed by Hyundai and Kia as a way to revolutionize the layout of an EV powertrain to more efficiently use space. In fact, the automakers say it’s not just for cars—the new drive system works with wheel sizes as small as four inches to as large as 25 inches.

For EV enthusiasts of a certain bent, there’s something a little inefficient about the way virtually every EV powertrain is laid out.

Not the battery in the middle, though—while it’s bulky and raises the overall height of EVs, it makes sense for weight distribution, although people working on structural carbon-fiber batteries have some different ideas about that. The problem is the EV drive unit, a bulky thing that contains the electric motor, some gearing, and usually some power electronics. These take up room between the axles and have to be packaged around.

An alternative is mounting each driven wheel’s electric motor to the wheel hub. The Lohner-Porsche Mixte Hybrid used this approach in 1900, but it has been largely eschewed other than by automakers still struggling with development—Lordstown, Endurance, and Aptera—in part because it does deleterious things to unsprung weight, and partly because being unsprung means the motor experiences all the same bumps and shocks as the wheel.Advertisement

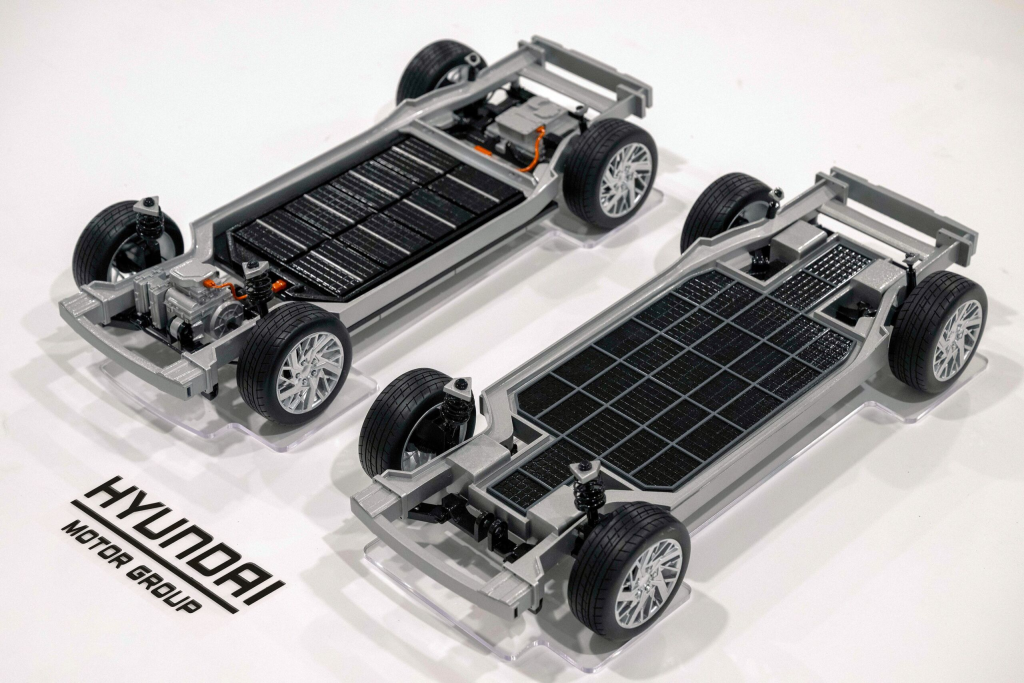

- Two EV powertrain layouts. On the left, one with conventional drive units that take up a lot of room between the axles. On the right, one with Uni Wheels that frees up the space between the axles for more battery. Hyundai

- The pinion gear multilink from a Uni Wheel drive system. Hyundai

- An assembled Uni Wheel drive system. Hyundai

The Uni Wheel does something different. Each driven wheel still has its own electric motor, but it’s mounted much closer to the suspension, freeing up more space between the axles (which could be used for more battery modules). The problem with doing that until now has been that conventional CV joints can’t cope with the angles that would be required, given the shorter driveshaft from motor to wheel.

So instead, the CV joint, driveshaft, and reduction gear all move into a new unit mounted in the wheel. This contains a planetary gear system that transfers drive from the motor to the wheel, but with a multilink arrangement between the pinion gears that allow the driveshaft to articulate through a wide range of motion.

Thinking beyond passenger EVs, Hyundai and Kia say that the Uni Wheel’s articulation and ability to scale down to small wheel sizes could enable a mobility chair or multi-wheeled robot to climb stairs “as smoothly as an escalator.”

Like many of the weird new engineering ideas that catch our eye, the Uni Wheel is still early in its development, so there’s no guarantee we’ll see it in production any time soon. But the two automakers say they’re continuing to refine the design, with expected improvements in efficiency, cooling and lubrication, and durability.